|

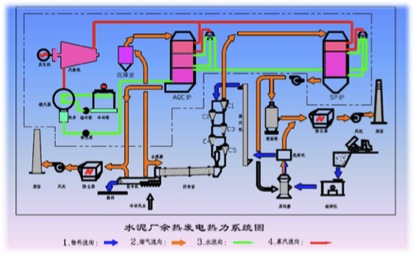

WHR (Waste Heat Recovery)

WHR production process is the technology that using the excess electrical energy converts to thermal energy. Cogeneration is not only energy saving, but also for environment protection. Waste heat boiler is the important equipment in WHR power generation, which utilize the heat and combustible matter in waste gas and waste fluid as heat source, producing steam for power generation. Waste heat used for power generation are: high temperature flue gas heat, chemical reaction heat, waste gas and waste liquid heat, low temperature heat (less than 200 ℃) and so on. Our company's WHR system is used for various industrial such as cement industry, glass, petrochemical, metallurgy, power and so on. Effectively reduce the carbon dioxide emissions, reduce the cost of electricity for customers. Our WHR technology uses a dual-pressure boiler technology, which is efficient use of the heat out of the exhaust emissions while optimizing the self-consumption ratio and has the industry-leading power efficiency. Depending on the environment, in some arid regions, we can use an efficient water-saving program to ensure the normal operation of WHR systems.

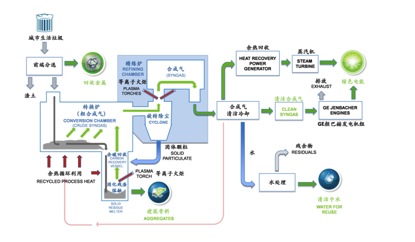

Waste Incineration Power Generation:

Burning garbage difficult part is how to deal with waste in a stable while reducing dioxin emissions! Our gas control type pyrolysis incinerator divided incineration process into secondary combustion chamber, a primary combustion chamber has garbage thermal decomposition and control the temperature within 700 ℃, so that garbage is decomposed by low temperature in the hypoxic state, then metal of Cu, Fe , Al and other metal elements is not oxidized, will greatly reduce the amount of dioxin; same time, since the HCl generation quantity is influenced by the concentration of residual oxygen, Hypoxia combustion will reduce the generation of HCl; Since it is difficult to generate a large amount under autoreduction. Since gas control type incinerator is solid bed, so it will not produce smoke, there will be no residual unburned carbon entering into the secondary combustion chamber. Combustible ingredients in garbage decomposed into combustible gas, and the introduce to burn in oxygen-rich secondary combustion. Temperature of secondary combustion chamber is about 1000 ℃ and flue length will keep flue gas can stay 2s above, to ensure that the dioxin and other toxic organic gases completely decomposed burning at high temperatures. Besides, bag filter can avoid Cu, Ni, Fe particles for catalytic formation of dioxins than when using electrostatic. Meanwhile, the introduction of the waste heat utilization system, which is maximized the use of waste heat. Using advanced combined process flue gas purification systems "SNCR denitration +semi-dry deacidification +dry deacidification + activated carbon adsorption bag filter ", configure mature whole plant automatic control systems and online monitoring system, flue gas emission value purification treatment are better than national standards, some indicators can reach EU standards in 2000.

Medium-voltage and Low-voltage power distribution equipment

Whole series of products are covered in a full range of medium and low-voltage distribution network, not only to help achieve intelligent electrical, but also for the realization of the establishment of the high efficiency, energy infrastructure, and buildings and industrial base.

MV switch cabinet:The main task is carrying out distribution by cost-effective and safely. Thus, we provide a variety of services and solutions to meet the customers’ worldwide requirement for MV system.

Outdoor MV switch cabinet: Our products are designed for the utilization in outdoor environments to minimize the number of moving parts, simple structure is capable of ensuring the long-term life of electrical working life and mechanical working life.

LV-voltage: To provide integrated solutions for power distribution

Our product series includes low voltage distribution cabinet, busbar trunking systems, and distribution cabinet, protection, and switch control, measurement, monitoring devices and switches sockets. Our modular, intelligent components and systems bring the benefit to our customers beyond imagination; also it is not limited to the entire life cycle. Our unique quality brings you to lead the future of design and a variety of innovative features.

|